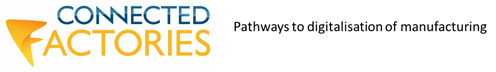

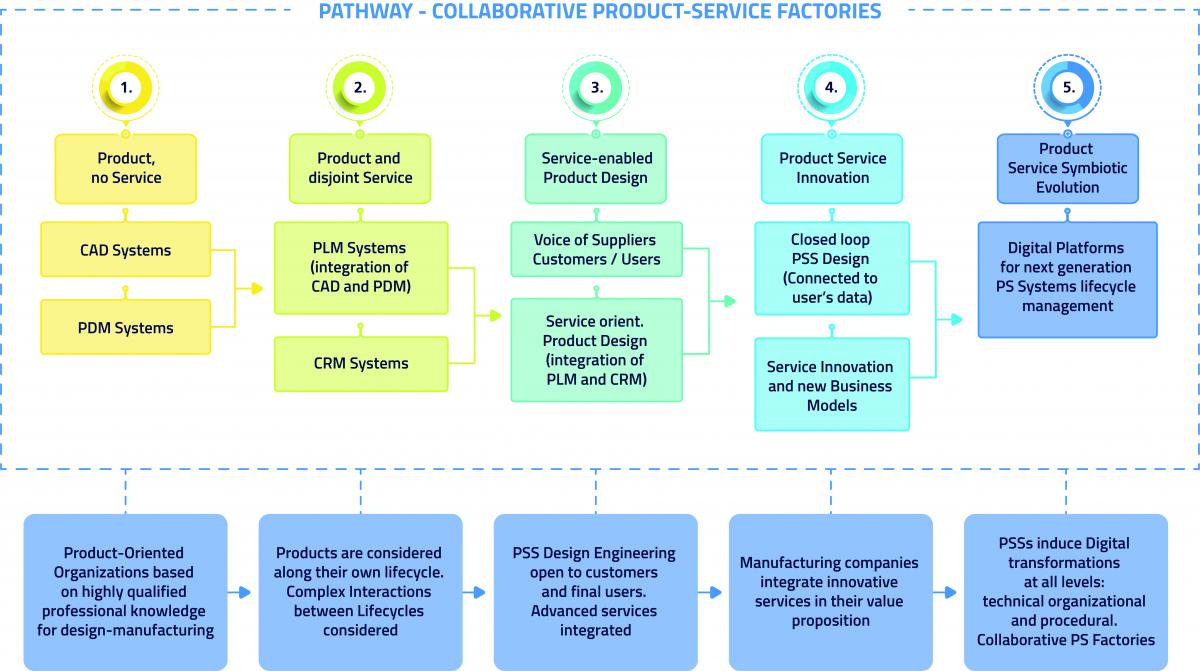

Collaborative Product-Service Factories pathway

Watch the Collaborative Product-Service Factories pathway video below:

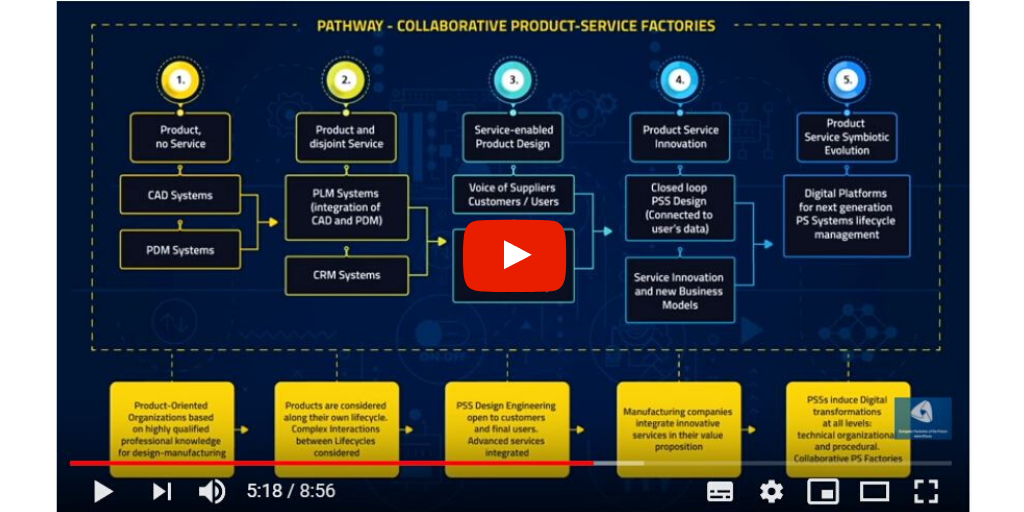

The collaborative product-service pathway is developed around the concept of servitisation as depicted by the picture below.

(This picture featured in a presentation at ConnectedFactories workshop on 26 September 2018).

The blue boxes on the bottom of the pathway focus on the business perspective, while the multi-colored boxes focus on the function/technological perspective of the pathway.

The manufacturing company is the primary perspective of the pathway. The pathway aims at capturing how the manufacturing company is progressively embracing a service oriented business model without dropping their product oriented business model

Many big companies have already understood the product-service concept, while SMEs have more difficulties to understand the association with services, in particular if they produce high-tech components. The danger for them is that they abandon their product after sales, while also missing the opportunity to create jobs in service / post-production jobs.

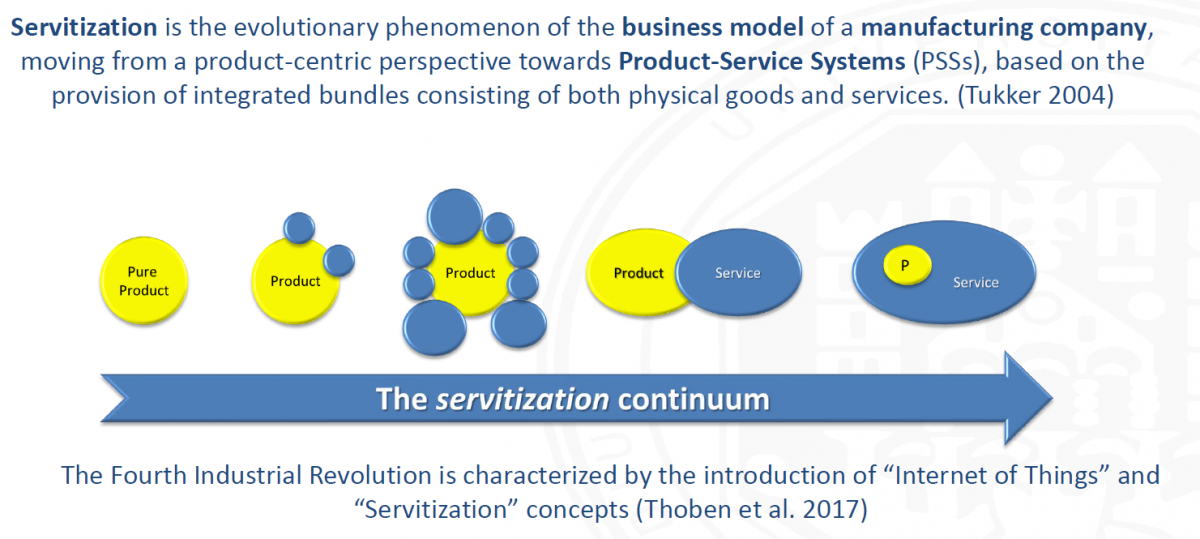

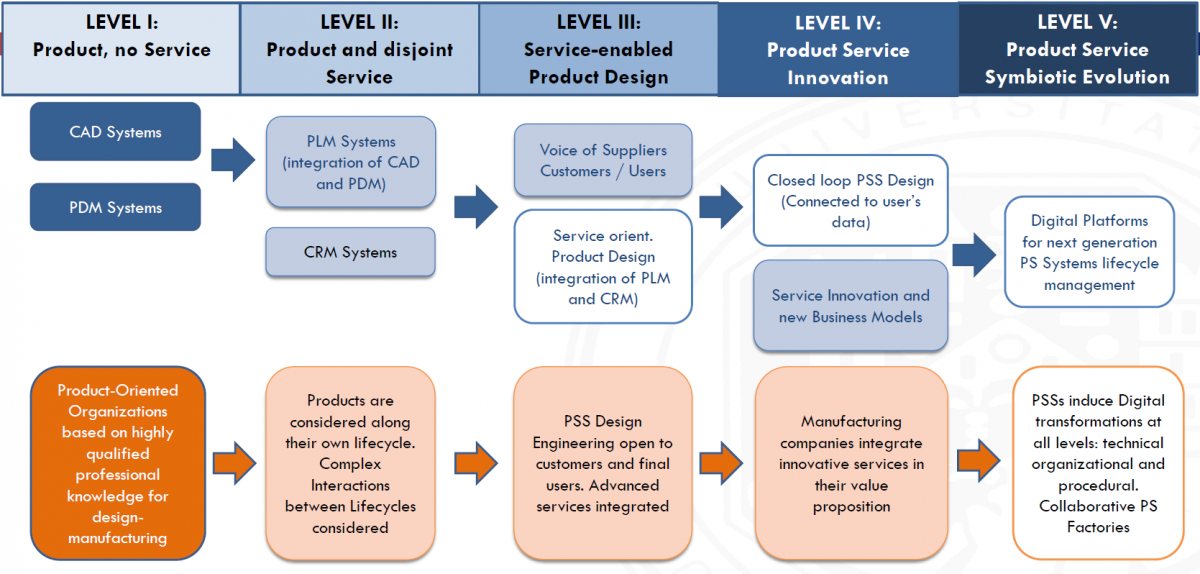

Collaborative Product-Services Factories pathway - Example from car industry (This picture featured in a presentation at ConnectedFactories workshop on 26 September 2018).

The pathway aims at capturing how the manufacturing company is progressively embracing a service-oriented business model without dropping the product-oriented business model

The need to progress towards service-innovation around the product has already been well understood by big companies. Some of the companies generate already around 50% of their revenues by the post-sale services (associated to training, maintenance, upgrades, etc…)

While big companies have already understood the product-service concept, SMEs have more difficulties to understand the association with services, in particular if they produce high-tech components. The danger for them is that they abandon their product after sales, while also missing the opportunity to create jobs in service and post-production jobs. This would also enable the shift of job profiles that are more associated to service-delivery.

Level 1 is the situation where the full focus of the manufacturing company is on the product and where it does not or hardly address the services associated to that product.

Level 2 of the pathway implies that the manufacturing company has understood the opportunity for growth and job creation offered by associating services to their product in a structured way. This understanding is linked to the fact that products are seen within their full lifecycle and the complex interaction across different stages of their lifecycle. From the technological point of view this requires that the product can be tracked and traced remotely. A product lifecycle system (PLM) system should be able to manage this information and also provide insight into the evolution of the product, even to the stage of retro-fitting, re-use and recycling. The fact that a manufacturer does not lose the connection or even the control of the product along its lifecyle is a pre-condition for the structured development of services that are closely associated and integrated with the product.

In level 3, design and engineering processes of the product are opened to the requirements and needs from the different stakeholders along the whole life-cycle of the product: suppliers, business partners, customers. So level 3 is about creating a collaborative environment beyond the boundaries of the manufacturing company.(This involvement of users is different when the users are consumer or professional users).

Level 3 is a preparation phase in order to be able to integrate innovative services in the product (design for service) in level 4. It also assures that the design of new products are not taking place in a silo anymore. It assures also that products, such as machine tools, are engineered more specifically according to the needs of the use of the machine tool.

Level 4 is the further evolution of the process started in level 3, where innovative services are designed (in partnership with the different stakeholders) and delivered, sometimes in cooperation with specialised ‘service’ companies. For example, predictive maintenance services are offered in cooperation with specialised predictive maintenance services companies. This requires the sharing of data among the different parties and the conclusion of associated B2B agreements.

Level 5 is when the company has transformed it’s business and product/services processes at all levels: embracing digital technologies (IoT, data analytics), integrating this with the hardware and manufacturing aspects (materials engineering, etc…), organisational aspects, where for instance sales people are both addressing the technical aspects as well as the business/service aspects.

In collaborative product service pathway, the link between the business objectives (shown in the bottom row of boxes) and the technological and digital aspect that enable to reach these business objectives, is less obvious that in the two previously presented pathway ‘Autonomous Smart Factories’ and ‘Hyperconnected Factories’.

The picture below reflect how some of the milestones are being addressed by mid-caps and advanced SMEs (very progressively with a lot of differences in maturity). Still there is a lot of very partial or totally unexplored territory here. ‘

Product-Services Factories pathway – SME perspective (only dark areas are partially addressed by SMEs) (This picture featured in a presentation at ConnectedFactories workshop on 26 September 2018)